Work hard play hard

09 November 2021

An engineers view on the

Hyundai Motor Company case

Work Hard

During a project in collaboration with the NVH Research Lab at Hyundai Motor Company in South Korea, we had the opportunity to execute a variety of source characterization techniques to study tire road noise. Within the family of Transfer Path Analysis techniques, there are quite a few methods available to characterize source components. Depending on the specific problem at hand and available equipment, either Blocked Forces or interface forces can be used to describe the source characteristics, and there are multiple ways to derive either of these types of forces (and moments).

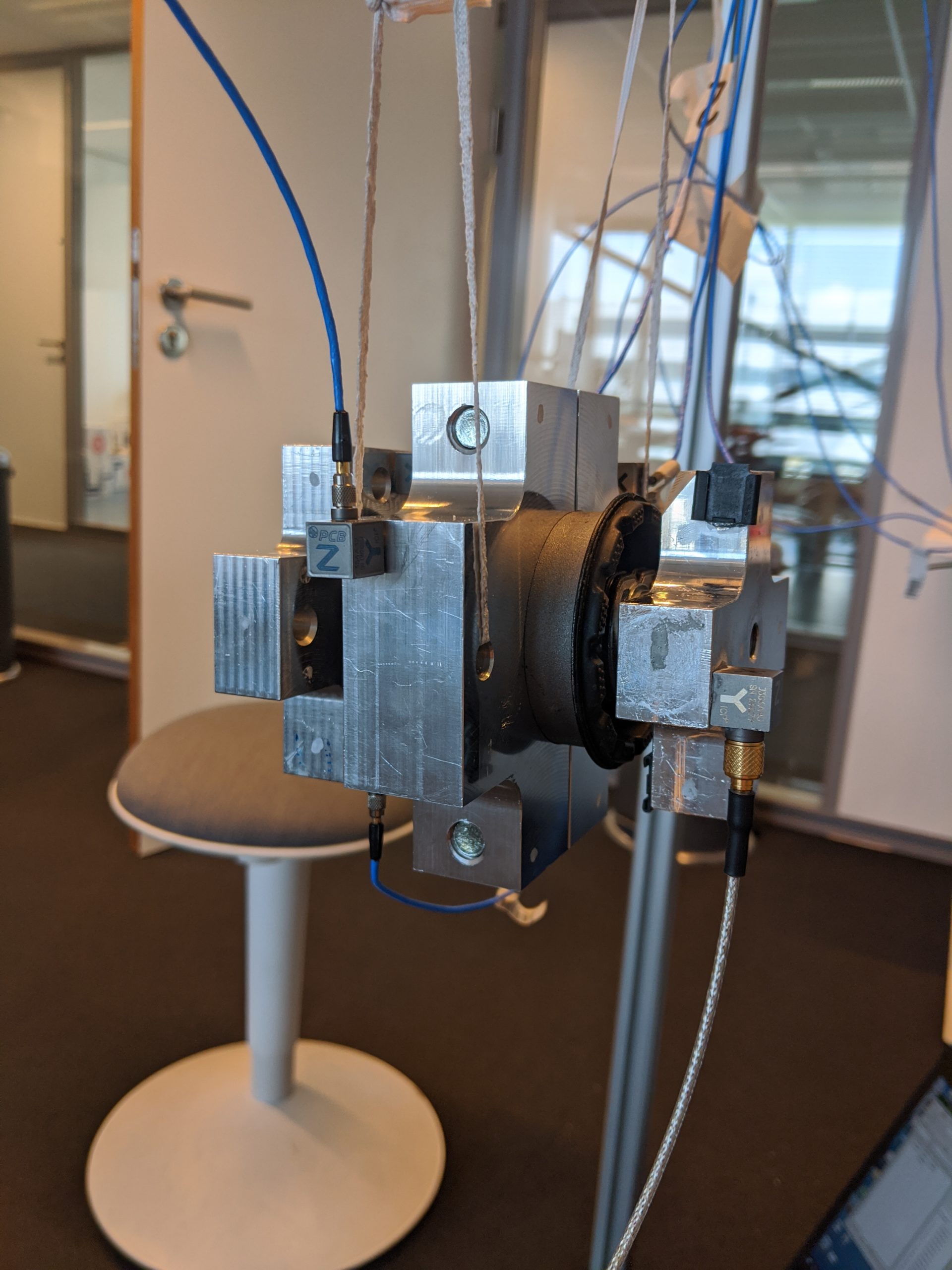

During this project, various configurations were tested, including a full vehicle, a vehicle with the suspension removed, a very rigid test rig, a softer test rig, and component-level tests to characterize the dynamic stiffness properties of the rubber bushings. This broad range of test data allowed us to determine the Blocked Forces in multiple ways (direct measurements and matrix inverse techniques). Additionally, the interface forces were calculated using several methods (matrix inverse, mount stiffness, conversion from Blocked Forces) enabling partial contribution analyses.

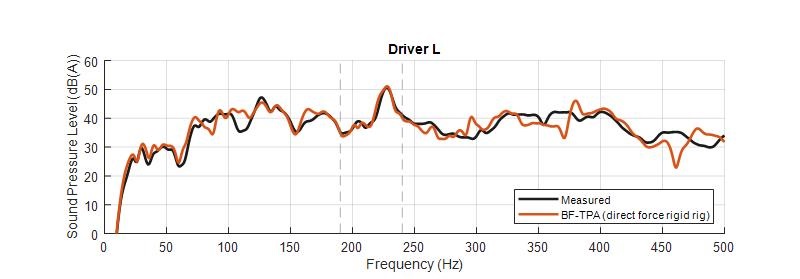

Combining such a broad range of data from different test configurations truly would not have been possible without the Virtual Point technology in DIRAC; this allowed us, for example, to easily apply the forces measured on the test rig to the full vehicle FRFs. Using this technology, we were able to validate all of the aforementioned source characterization methods. Particularly, the Blocked Forces measured on the rigid test rig could be directly applied to the vehicle FRFs and produced extremely accurate results up to higher frequencies (see figure), as Hyundai’s test rig was designed to be very rigid. The results from this project give both us and the customer the confidence to employ any of these validated techniques in future projects.

Play Hard

Through our engineering consultation projects, we’ve gotten to see some amazing places in the world that we might not have gone to otherwise. Although VIBES is based in Europe, we’ve had a lot of enthusiastic customers in the automotive sector of Asia, and specifically in South Korea.

While our Korean trips are usually filled with lots of NVH testing during the weekdays, we get to spend the evenings and weekends getting to know the local culture.

From hiking in the Korean mountainside, to exploring the busy streets around Gangnam square, to mastering our chopsticks skills, we’ve really enjoyed the time we’ve gotten to spend in Korea. The locals really go out of their way to make foreigners such as ourselves feel welcome in their country. It’s very much appreciated, especially when you need to go on a culinary adventure after a long day of testing. We look forward to our next trip to Korea or wherever else the projects take us!